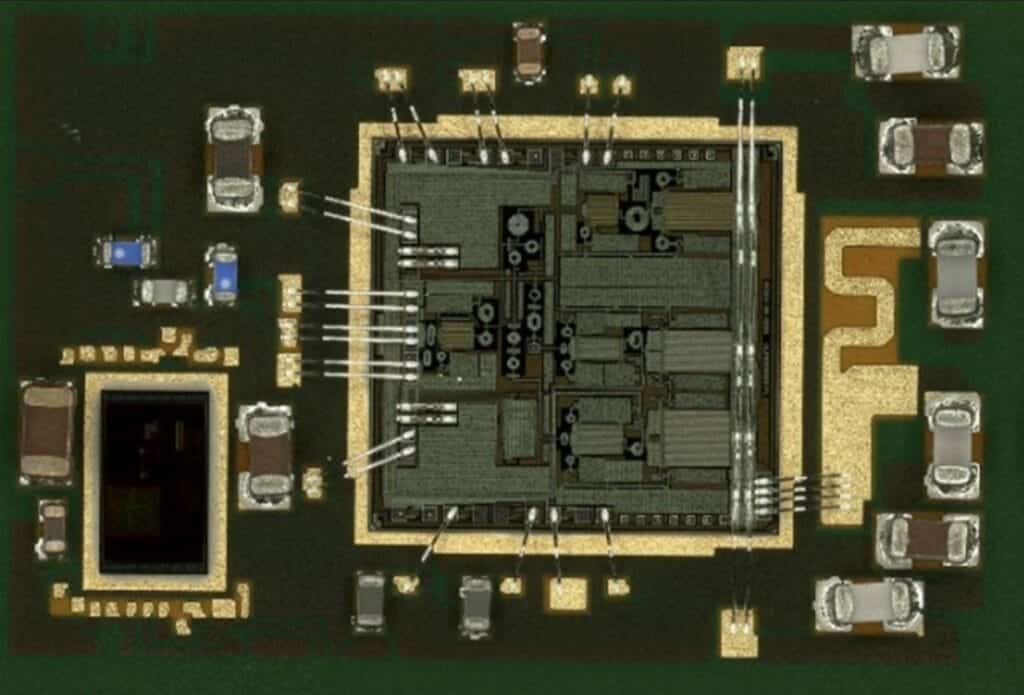

SERMA Microelectronics uses two types of hybrid technology:

- Hermetic hybrids: SERMA Microelectronics offers a technological service including the production of hermetic hybrids on thick-film substrates and so-called MCM modules with chips and components on HTCC substrates.

- Non-hermetic hybrids: microsystems produced using combined assembly techniques (chip/SMD) on thin-film or organic substrates, protected with resin or gel.

In the aeronautics, space and defence sectors, integration (decreased weight and size), combined with the need to optimise costs, has become a decisive factor in terms of competitiveness and differentiation.

Hybrids are specific components that combine several electronic functions, requiring a high degree of operational integration and resistance to environmental constraints. They are heterogeneous objects that combine the best integration technologies.

They require the use of microelectronic integration technologies using chip and SMD placement on substrates, including power elements.

In addition, for integration purposes, it is possible to:

- Treat part of the module function in the form of a specific component (ASIC) that will be placed on the chip

- Use solder-paste printing technology to treat resistors that can then be adjusted by laser ablation

These hybrids have the following advantages:

- Compact structure: reduced weight, reduced volume

- Enhanced reliability

- Enhanced quality (re-use of qualified functions, re-use of controlled technological building blocks, etc.)

- Resistance to severe environments

This combination of technologies enables us to deal with autonomous functions, such as engine control, firing devices based on digital and analogue sequences or monitoring of critical systems.

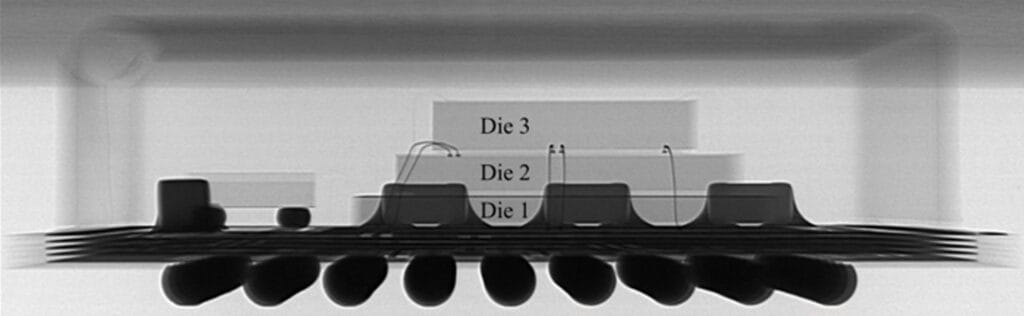

MODULES 3D

Sensors need to be ever more accurate, reliable, effective and small. One solution is to integrate the physical sensor with its electronic component (control, filtering, digitalisation, wired or wireless communication).

SERMA Microelectronics offers various solutions to the issue of how to integrate chips and components in a small, restricted space.

In addition, environmental constraints often require hermetic sealing (as regards the electronic components) and measuring devices (as regards the physical sensor).

This internal sequencing can become highly complex and requires a combination of several technological building blocks, such as:

- Mixed placement/wiring of chips/components

- 3D interconnection between different substrates or PCBs

- Internal protection via the application of gel or resin or via inerting (nitrogen, Argon, vacuum) and hermeticity

- Bonding of a quartz or glass window

- Slow polymerisation

- Dynamic adjustment